Master Your Mist: Demystifying Essential Sprayer Parts

Sprayers are essential in various industries, such as agriculture, landscaping, and pest control. They play a crucial role in the distribution of liquids, including pesticides, fertilizers, and other chemicals.

However, not everyone understands how sprayers work or the parts that make up this vital equipment. In this guide, we will demystify essential sprayer parts to help you better understand the inner workings of sprayers and how to maintain them.

Why is it Important to understand Essential?

One of the main reasons why it’s important to understand essential sprayer parts is because it allows you to maintain and repair your equipment properly. A mist sprayer consists of

- Nozzles,

- Tanks

- Pumps,

- Hoses, etc.

They work together to create the perfect mist. If any of these parts malfunctions or breaks down, it can affect the performance of your entire system.

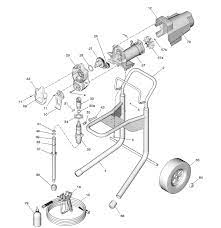

Understanding Sprayer Parts

The first step in mastering your sprayer is understanding its parts. The most common types of sprayers are hand-held, backpack, and tow-behind. While their designs may vary, they all have similar essential components that make them function effectively.

Titan paint sprayer parts include:

- The pump is the heart of the sprayer and creates pressure to distribute liquids. It can be either manual, powered by a hand lever, or motorized.

- The tank holds the liquid being sprayed and can come in varying sizes depending on the type of sprayer.

- The nozzle is responsible for controlling the direction and pattern of the spray. It can be adjustable or fixed, depending on the type of sprayer.

- The hose connects the pump to the nozzle and allows liquid transfer under pressure.

- The wand or lance is an extension of the hose that allows you to reach areas that are harder to access.

- The strainer helps to filter out debris and prevent clogging of the nozzle.

- This component measures the pressure inside the tank and allows the user to adjust it accordingly.

- The shut-off valve regulates liquid flow from the tank to the nozzle.

Types of Pumps

As mentioned earlier, the pump is a vital part of the sprayer. Without it, the liquid would not be able to reach the nozzle for spraying. There are three main types of pumps used in sprayers:

Piston Pump

This type of pump uses a piston and cylinder mechanism to create pressure.

Diaphragm Pump

A diaphragm pump uses a flexible diaphragm to create pressure and is best suited for handling harsh chemicals.

Centrifugal Pump

This type of pump uses centrifugal force to distribute the liquid and is typically used in larger sprayers.

Factors Affecting Pump Performance

Knowing the type of pump your sprayer has is essential, but understanding the factors that affect its performance is equally important. These include:

Type of liquid

Different liquids have different viscosity levels, affecting the pump’s ability to create pressure.

Size and length of hose

The longer and narrower the hose, the more difficult it is for the pump to maintain a constant pressure.

Nozzle size

A smaller nozzle will require more pressure from the pump to distribute the liquid.

Number of nozzles

The more nozzles a sprayer has, the more pressure the pump needs to distribute the liquid effectively.

Pump maintenance

Regular maintenance and cleaning of the pump are crucial for optimal performance.

Maintenance Tips for Essential Sprayer Parts

Now that you understand your sprayer’s different titan paint sprayer parts, and how they work, it’s important to know how to maintain them for long-lasting performance. Here are some maintenance tips for essential sprayer parts:

- Check the pump regularly for any signs of wear or damage. Replace worn-out seals and O-rings, and clean the valves and pistons.

- After use, empty and rinse the tank thoroughly to remove any residue. This will prevent clogging and prolong the life of your sprayer.

- Clean out any debris or residue from the nozzle regularly, and replace worn-out nozzles promptly.

- Check for leaks, cracks, or blockages in the hose and replace it if necessary. Keep the hose straight and free from kinks to maintain proper pressure flow.

- Inspect for wear and tear, and replace any damaged parts promptly. Lubricate any moveable parts regularly to prevent rusting.

- Clean the filter after each use to ensure it is free from debris and clogs.

- Regularly check the accuracy and functionality of the pressure gauge. If it is not working correctly, replace it immediately.

- Check for leaks or damage in the shut-off valve and replace if needed. Make sure to close the valve when not in use to prevent leakage.

Conclusion

Sprayers are essential for agriculture, landscaping, or pest control. Understanding the different parts of your sprayer and how they work is crucial for proper maintenance and optimal performance.

Regular maintenance of essential sprayer parts will prolong their life and ensure this important equipment’s safe and effective use. This guide lets you master your mist and make the most out of your sprayer. So, get out there and start spraying with confidence! So, let’s grab your sprayer and start spraying like a pro!