Understanding Heat Pipes: What Does A Heatsink Do

If you’ve ever wondered, “what does a heatsink do?” the answer is both simple and vital: it prevents electronic devices from overheating. A heatsink absorbs heat from components like CPUs, GPUs, and power transistors, then disperses it into the surrounding air to maintain safe operating temperatures. Without this essential component, devices can experience performance drops, instability, or even permanent damage. In this article, “Understanding Heat Pipes: What Does a Heatsink Do,” we’ll explore how heatsinks work, their connection with heat pipes, and why they are crucial for modern technology.

What Is a Heatsink?

A heatsink is a device that helps keep electronic components cool by absorbing heat and releasing it into the surrounding environment. It is usually made of metal and works through conduction (drawing heat from the component), convection (releasing heat into the air), and sometimes radiation. The main purpose of a heatsink is to prevent overheating, which can damage the component or reduce its performance.

How Does a Heatsink Work?

A heat sink is a device that prevents electronic components, such as CPUs or LEDs, from overheating by absorbing excess heat and releasing it into the surrounding air.

- Heat Absorption (Conduction): The heat sink’s base touches the hot component. Metals like aluminum or copper, which conduct heat well, draw the heat away from the component.

- Heat Distribution: Heat spreads evenly across the heat sink to prevent hot spots, keeping the component safe.

- Heat Dissipation (Convection): Fins or extended surfaces help transfer heat to the surrounding air. Warm air rises, cooler air replaces it, and heat is carried away naturally.

- Enhanced Cooling: In high-performance setups, fans or heat pipes can be added. Fans boost airflow, while heat pipes move heat more efficiently using phase-change technology.

Heat sinks keep electronics running efficiently, safely, and for a longer lifespan.

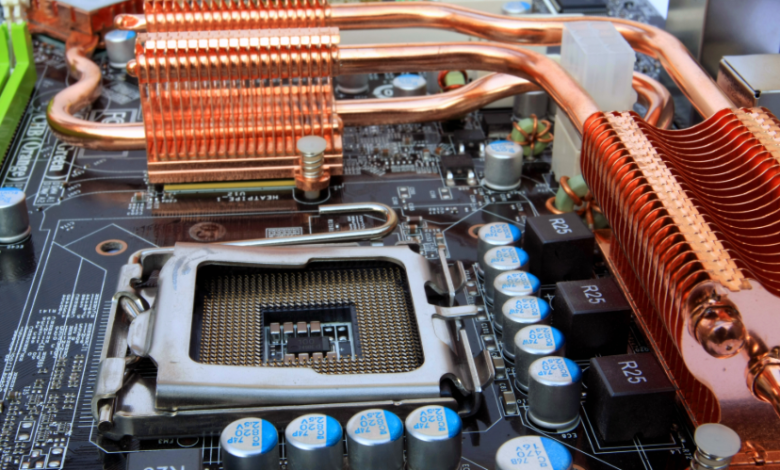

The Role of Heat Pipes in Modern Cooling

Heat pipes are critical components in modern cooling systems, efficiently transferring heat from hot areas to cooler regions. They rely on phase-change technology, where liquid vaporizes and condenses, allowing rapid heat movement with minimal temperature difference. This makes them ideal for compact, high-performance devices.

Key Roles:

- Efficient Thermal Transport: Quickly transfers heat away from high-temperature zones.

- Compact and Lightweight Design: Ideal for modern electronics where space is limited.

- Enhanced Device Reliability: Prevents overheating and ensures consistent performance.

- Energy-Efficient Operation: Functions passively without external power input.

- Wide Application Range: Used in electronics, aerospace, automotive, and renewable energy systems.

Heat pipes are a cornerstone of modern cooling technology, enabling smaller, faster, and more powerful devices to operate safely and efficiently.

Why Are Heatsinks Important?

Heatsinks are essential components in thermal management systems because they dissipate heat generated by electronic or mechanical components, preventing overheating and ensuring reliable operation. By increasing the surface area exposed to air, heatsinks allow heat to be efficiently transferred away from critical parts.

Key Reasons Heatsinks Are Important:

- Prevents Overheating: Protects components like CPUs, GPUs, and power transistors from thermal damage.

- Enhances Performance: Maintains optimal operating temperatures for consistent performance.

- Extends Lifespan: Reduces thermal stress, increasing the durability and longevity of devices.

- Improves System Stability: Keeps electronics running efficiently under high workloads.

- Supports Passive Cooling: Often works without moving parts, reducing noise and energy consumption.

Heatsinks are vital for keeping modern electronics cool, efficient, and reliable, forming the foundation of effective thermal management.

Types of Heatsinks and Cooling Systems

1. Active Heat Sinks

Active heat sinks use powered components, such as fans or liquid cooling pumps, to boost cooling performance. These mechanisms actively circulate air or coolant across the heatsink’s surface, enhancing heat dissipation and maintaining stable operating temperatures even under heavy workloads.

Advantages:

Superior cooling efficiency for high-performance components.

- Consistent temperature control under demanding conditions.

Built for high-performance systems.

Drawbacks:

Generates noise from moving parts.

- Higher power consumption.

More complex installation and occasional maintenance are required.

2. Passive Heat Sinks

Passive heat sinks cool components without using fans or other powered devices. They rely on natural airflow and the heat-conducting properties of materials like aluminum or copper. Their wide fins or large surfaces help spread and release heat efficiently.

Advantages:

Completely silent operation.

- High reliability with no moving parts to fail.

Well-suited for low-power or noise-sensitive applications, including smartphones, IoT devices, and LED lighting systems.

Drawbacks:

Limited cooling capacity in high-temperature or poorly ventilated environments.

Less effective for components that generate significant heat loads.

3. Hybrid Heat Sinks

Hybrid heat sinks integrate both active and passive cooling techniques, combining the efficiency of mechanical components (like fans or pumps) with the reliability of large surface areas and conductive materials. Many hybrid designs also include heat pipes to enhance heat transfer between components and cooling fins.

Advantages:

Balanced performance between cooling efficiency and noise reduction.

- Excellent for systems requiring both power and quiet operation.

Commonly used in servers, gaming PCs, and advanced computing systems.

Drawbacks:

Higher manufacturing cost and design complexity.

- Requires periodic maintenance due to multiple active elements.

Risk of reduced reliability if an active component fails.

Choosing the right type ensures optimal performance, longer component lifespan, and reliable operation across a range of electronic devices.

See also: Vibe Coding and Developer Wellbeing: A New Approach to Tech Culture

Applications of Heatsinks in Everyday Technology

Heat sinks are essential for keeping electronic devices cool, efficient, and reliable by removing excess heat. They are widely used across various technologies:

1. Computers and Consumer Electronics

Heat sinks cool critical components such as CPUs, GPUs, and chipsets, preventing overheating, system slowdowns, and instability. Passive heat sinks rely on natural airflow, while active heat sinks use fans to enhance cooling performance.

2. LED Lighting Systems

LEDs produce heat that can reduce both brightness and lifespan. Heat sinks absorb and dissipate this heat, ensuring LEDs remain bright and durable over time.

3. Power Electronics and Amplifiers

Heat sinks cool high-heat devices such as inverters, voltage regulators, and audio amplifiers, enhancing their efficiency and ensuring reliable operation.

4. Automotive and Industrial Systems

In automotive electronics, heat sinks regulate temperatures in engine control units, power electronics, and LED systems. In industrial machinery, they prevent overheating and ensure stable operation under high temperatures and vibrations.

Heat sinks keep electronic and industrial components cool, reliable, and durable.

Maintaining and Optimizing Cooling Performance

Proper maintenance and thoughtful design ensure heat sinks remain effective, keeping devices cool, efficient, and extending their lifespan.

Maintenance Tips

- Regular Cleaning: Dust and debris can block fins and airflow. Use compressed air or a soft brush to clean heat sinks regularly.

- Proper Thermal Paste Application: Thermal paste improves heat transfer between the heat sink and the component. Reapply it periodically, as it can dry out or degrade over time.

- Ensure Adequate Airflow: Keep heat sinks unobstructed and ensure proper airflow, using fans or ventilation if needed for effective cooling.

- Monitor Temperatures: Use software tools to track component temperatures. Rising temperatures may indicate maintenance or design issues before serious problems occur.

Design Optimization Strategies

- Enhance Fin Design: Optimize fin material, spacing, thickness, and height to increase surface area and improve heat dissipation.

- Use Heat Pipes: Heat pipes transfer heat efficiently from the source to the heat sink, improving performance in high-power applications.

- Choose High-Conductivity Materials: Select metals such as copper or anodized aluminum for heat sinks because they transfer heat efficiently. Anodizing or other surface treatments further increase durability and protect against corrosion.

- Use CFD Simulations: Computational Fluid Dynamics (CFD) helps optimize heat sink design by improving geometry and airflow, resulting in more efficient cooling.

Regular maintenance and thoughtful design keep heat sinks effective, ensuring better cooling, improved device performance, and longer component lifespan.